Special Sewing Machines

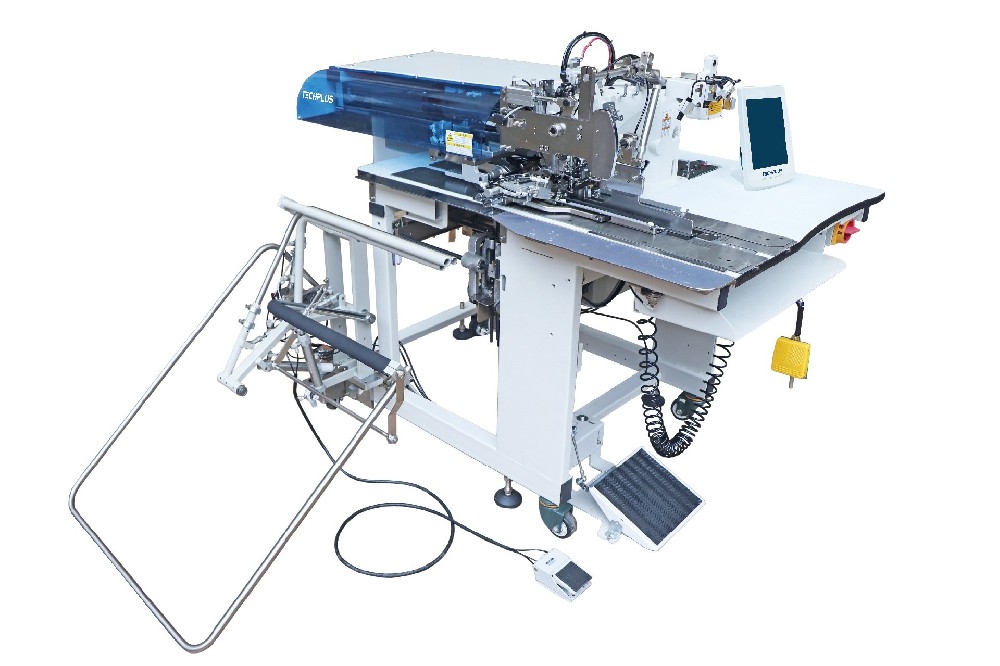

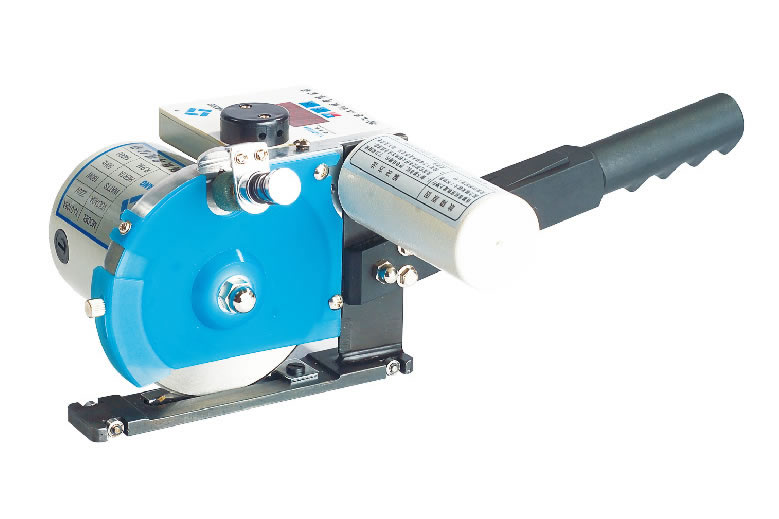

Template Programmable Pattern Sewing Machine

Multi-Needle Sewing Machine Series

Lockstitch Sewing Machine Series

WELCOME TO YUEQING JIEXING SHENGJIA COMPANY

One-stop purchasing platform, A professional assistant at your side

Featured products

FROM THE NEWS

2121-01-30

How to choose a computer sewing machine?

The so-called computer-controlled sewing machine is popularly speaking, it is the computer sewing machine. With the continuous adjustment of the market and consumption structure, the low- and medium-speed industrial sewing machine can no longer meet the production needs, and the sewing machine is de

2121-01-30

Computerized sewing machine equipment maintenance and maintenance methods

Computer sewing equipment maintenance and maintenance methods1. A reasonable working environment for computer sewing equipment. First of all, do not install the equipment in a place with strong electric noise or high-frequency welding. The strong electric noise will affect the equipment or cause the